Top queries answered

This section addresses frequently asked questions effectively.

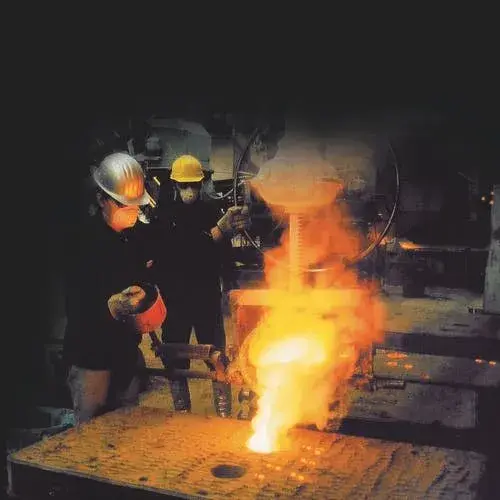

1. Aluminum Casting

Properties: Lightweight, corrosion-resistant, and excellent for heat dissipation.

Common Uses: Automotive parts (engine blocks, wheels), electronics enclosures, aerospace components, and industrial machinery.

Casting Methods: Die casting, sand casting, investment casting, and permanent mold casting.

2. Gunmetal (Bronze) Casting

Properties: A copper alloy with tin and zinc, known for its strength, corrosion resistance, and wear resistance.

Common Uses: Marine hardware, bearings, bushings, valves, and pumps.

Casting Methods: Sand casting, centrifugal casting, and investment casting.

3. Brass Casting

Properties: An alloy of copper and zinc, known for its excellent machinability, good corrosion resistance, and attractive appearance.

Common Uses: Plumbing fittings, electrical connectors, decorative items, musical instruments, and marine hardware.

Casting Methods: Sand casting, investment casting, and die casting.

4. Zinc Casting

Properties: High strength, good corrosion resistance, and low melting point, making it ideal for complex shapes and high-volume production.

Common Uses: Automotive components, die-cast toys, hardware, and electrical components.

Casting Methods: Die casting is the most common for zinc alloys, as it allows for high precision and intricate designs.

Casting Techniques:

The casting methods you might use for these materials can include:

Die Casting: Ideal for high-volume production with precise, complex geometries (especially for zinc and aluminum).

Sand Casting: Versatile and cost-effective, suitable for small to medium runs (used for aluminum, brass, and gunmetal).

Investment Casting: Used for high-precision, complex parts with a smooth surface finish (for gunmetal, brass, and aluminum).

Permanent Mold Casting: Combines sand and die casting methods, suitable for medium runs with aluminum.

Considerations for Each Material:

Aluminum: Requires careful temperature control due to its sensitivity to oxidation.

Gunmetal: The addition of tin ensures better corrosion resistance, especially in marine environments.

Brass: The balance between copper and zinc is critical for achieving the right strength and workability.

Zinc: Though easy to cast, zinc can be prone to cracking or brittleness if the casting process isn’t properly controlled.

If you need specific advice on casting processes or material selection for particular applications, feel free to provide more details!1. Aluminum Casting

Properties: Lightweight, corrosion-resistant, and excellent for heat dissipation.

Common Uses: Automotive parts (engine blocks, wheels), electronics enclosures, aerospace components, and industrial machinery.

Casting Methods: Die casting, sand casting, investment casting, and permanent mold casting.

2. Gunmetal (Bronze) Casting

Properties: A copper alloy with tin and zinc, known for its strength, corrosion resistance, and wear resistance.

Common Uses: Marine hardware, bearings, bushings, valves, and pumps.

Casting Methods: Sand casting, centrifugal casting, and investment casting.

3. Brass Casting

Properties: An alloy of copper and zinc, known for its excellent machinability, good corrosion resistance, and attractive appearance.

Common Uses: Plumbing fittings, electrical connectors, decorative items, musical instruments, and marine hardware.

Casting Methods: Sand casting, investment casting, and die casting.

4. Zinc Casting

Properties: High strength, good corrosion resistance, and low melting point, making it ideal for complex shapes and high-volume production.

Common Uses: Automotive components, die-cast toys, hardware, and electrical components.

Casting Methods: Die casting is the most common for zinc alloys, as it allows for high precision and intricate designs.

Casting Techniques:

The casting methods you might use for these materials can include:

Die Casting: Ideal for high-volume production with precise, complex geometries (especially for zinc and aluminum).

Sand Casting: Versatile and cost-effective, suitable for small to medium runs (used for aluminum, brass, and gunmetal).

Investment Casting: Used for high-precision, complex parts with a smooth surface finish (for gunmetal, brass, and aluminum).

Permanent Mold Casting: Combines sand and die casting methods, suitable for medium runs with aluminum.

Considerations for Each Material:

Aluminum: Requires careful temperature control due to its sensitivity to oxidation.

Gunmetal: The addition of tin ensures better corrosion resistance, especially in marine environments.

Brass: The balance between copper and zinc is critical for achieving the right strength and workability.

Zinc: Though easy to cast, zinc can be prone to cracking or brittleness if the casting process isn’t properly controlled.

For inquiries, contact our support team at metalworksks@gmail.com, call +91 98689 33037, or chat with us live on our site. We're here 24/7 to help you.

We’re dedicated to delivering timely and effective solutions to guarantee your satisfaction.

Our talented crew

Mr. Surender